Production & Service

Production & Service: Your top quality bouncy castle partner

Trust in our many years of experience in producing high-quality bouncy castles and benefit from an all-round service that leaves nothing to be desired. From professional cleaning and repairs to professional storage and regular assessments - we take care of every detail so that you can always have carefree fun.

- Quality & Safety: Production according to EN 14960 and TÜV-certified materials

- Comprehensive service: Repairs, cleaning, reports and storage from a single source

- Custom-made products: As a producer, we are your partner for tailor-made solutions

Everything from a single source: production and service

As a producer of inflatable play equipment and advertising media, we have specialized in custom-made products. Depending on your use, you can Buy bouncy castles or for individual actions Rent bouncy castles. We attach great importance to quality and respond individually to your wishes.

Our all-round service does not end after production - we accompany you from the first idea to the long-term maintenance of your products.

- Repair: Whether sewing, welding or gluing – we will quickly get your inflatable advertising media and bouncy castles back into shape.

- Cleaning & Care: Your bouncy castle shines in new splendor - for cleanliness and value retention.

- Storage & product management: From safe storage to on-site handling – we take care of all the steps for you.

- Reports & Certification: We check according to relevant safety standards and, if necessary, issue a report for official purposes.

Innovative bouncy castle manufacturer: Transparent production

We manufacture high-quality bouncy castles using the latest technology and transparency. Every step – from planning to completion – is traceable to ensure long-lasting and safe products.

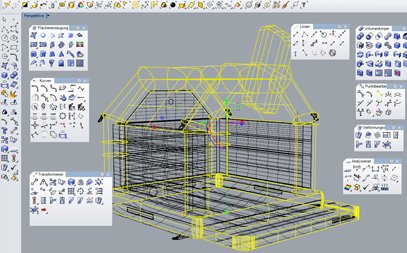

Precise 3D planning for long-lasting inflatables

The quality of our bouncy castles starts with the planning. By using state-of-the-art 3D computer models, we can precisely design and simulate every detail of the structure in advance. This precise planning allows us to identify and address potential vulnerabilities before production begins. This is how we ensure that our bouncy castles are not only visually appealing, but also particularly durable and robust. Thanks to this technology, we can use materials optimally to ensure even loading and significantly extend the lifespan of the inflatables. Trust in our know-how for products that will provide years of enjoyment.

First-class materials for maximum robustness

Ours customized bouncy castles are made from high-quality, three-layer PVC fabric that is made in Germany. The material is characterized by its 680 g/m² thickness and a triple plastic coating. It is UV-resistant and has high tear resistance. It also meets strict safety requirements, is flame-retardant (B1), produces little smoke (Q1) and does not form burning drops (TR1). In addition, the tarpaulins are dirt-repellent, waterproof, abrasion-resistant, kink- and UV-resistant, which significantly increases the lifespan of our products. This excellent quality guarantees maximum safety and stability of our bouncy castles, even during intensive use.

Brilliant graphics thanks to 4C & 5C printing technology

Thanks to 4C and 5C printing technology, PVC tarpaulins in large format printing now reach a completely new level of color brilliance and depth of detail. The main difference between these two techniques is that 5C technology allows direct printing on colored PVC material, while 4C printing requires a white background. With the additional fifth color, often white or a special varnish, 5C technology achieves particularly bright and precise colors on dark or colored surfaces. This opens up completely new possibilities for your demanding printing applications inflatable advertising – from classic advertising technology to creative artistic projects and designs.

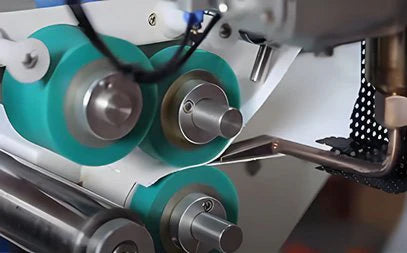

Perfect cuts with the PVC cutter plotter

By using PVC cutter-plotters, the cuts for orders and complex designs are carried out with the highest precision, ensuring outstanding quality. This advanced technology captures even the finest details of your designs and cuts them with extreme precision, making every production a true masterpiece. Also everything our event modules Benefit from this precise workmanship - each element is manufactured with millimeter precision and assembled with a precise fit. Thanks to this high level of accuracy, you can trust that each piece is manufactured exactly to your specifications, significantly increasing your customers' satisfaction. The efficient cutting process also reduces material waste and optimizes the entire production, which is both cost-saving and environmentally friendly.

High frequency welding technology for strong connections

For our airtight products such as pneumatic Archways, Advertising cubes, tents, pools and advertising columns, we use the latest high-frequency welding. Our Miller T-600 Flex from WDN fuses PVC materials precisely and permanently - without any adhesives. This ensures clean, welded panels, maximum stability and a first-class appearance. In contrast to conventional sewing or gluing techniques, high-frequency welding offers an absolutely airtight and watertight connection - ideal for all products that do not require a continuous blower.

COATS polyester thread for reliable seams

Our thread is a high-strength sewing thread that is particularly suitable for inflatable structures such as event modules, Giant slides, bouncy castles, tents and promotional products. Thanks to its special lubrication and robust polyester structure, it offers excellent abrasion resistance and durability, which is crucial to the longevity of these products. The yarn ensures even and smooth processing, even with thick and stressed materials such as PVC. It ensures that the seams of inflatable structures remain waterproof, stable and resistant to high loads. Rely on COATS to ensure maximum safety and durability for your inflatable products.

craftsmanship with Dürkopp Adler Sewing machines

When making ours Bouncy castles We rely on the proven German quality Dürkopp Adler Sewing machines. These high-performance machines are known worldwide for their precision and reliability, especially when processing extremely robust materials such as PVC. By using these machines, our seamstresses can hand-craft the long-lasting, strong seams that are critical to the safety and durability of our inflatables. Every seam is processed with a lot of experience, care and the highest precision to ensure exceptional durability and resilience, even with intensive, daily use.

Continuous improvements for increased durability

We are continuously working on improving our bouncy castles, Bull riding facilitiesto improve and further develop event modules. Through years of experience, we specifically identify the particularly stressed areas and reinforce them with optimized materials and sewing techniques. Every production is carefully monitored to ensure that vulnerabilities are identified and resolved early. Our improvements range from stronger seams to more durable materials in high-wear areas, significantly increasing the lifespan and safety of our inflatables. This is how we ensure that our products last over time, even under intensive use.

Certified safety for carefree fun

Our bouncy castles & advertising medium meet the strict requirements of the European standard EN 14960, which was specifically developed for inflatable play equipment. This standard regulates essential safety aspects such as material thickness, tear resistance, stability and secure attachment points to ensure maximum safety. Before a bouncy castle leaves our factory, it is extensively tested to ensure that all relevant safety and quality standards are met. This is how we guarantee that our products not only bring joy, but also meet the highest standards of longevity and safety. Trust in our quality for safe events.

Ready for something special?

Thanks to our in-house production and comprehensive services, we implement your wishes quickly and reliably.

+43 (0) 3332 65185

Monday – Friday: 8:00 a.m. – 12:00 p.m. & 1:00 p.m. – 4:00 p.m